Features

- Eco-friendly:

Crafted from recycled plastic, this durable unit is designed to withstand constant use, ensuring robust performance in various settings. - Reliable operation:

Developed by leading experts, it features a stainless steel housing for hygienic and reliable dehumidification. - Full control:

Equipped with a wide range of controllers and sensors, it allows precise management of humidity and dew point, compatible with all external controller types. - Energy-efficient:

Optimized to minimize energy consumption while maximizing dehumidification efficiency, resulting in low operational costs. - User-friendly:

Easy to install, operate, and maintain, with advanced microprocessor-based control units that provide the right degree of automation.

Specs

| Process air | 240 m³/h |

| Dehumidification capacity | up to 1,5 kg/h |

| Electrical connection power | 0,78 – 1,97 kW |

| Connection voltage | 230 / 1 V / Ph+N+PE |

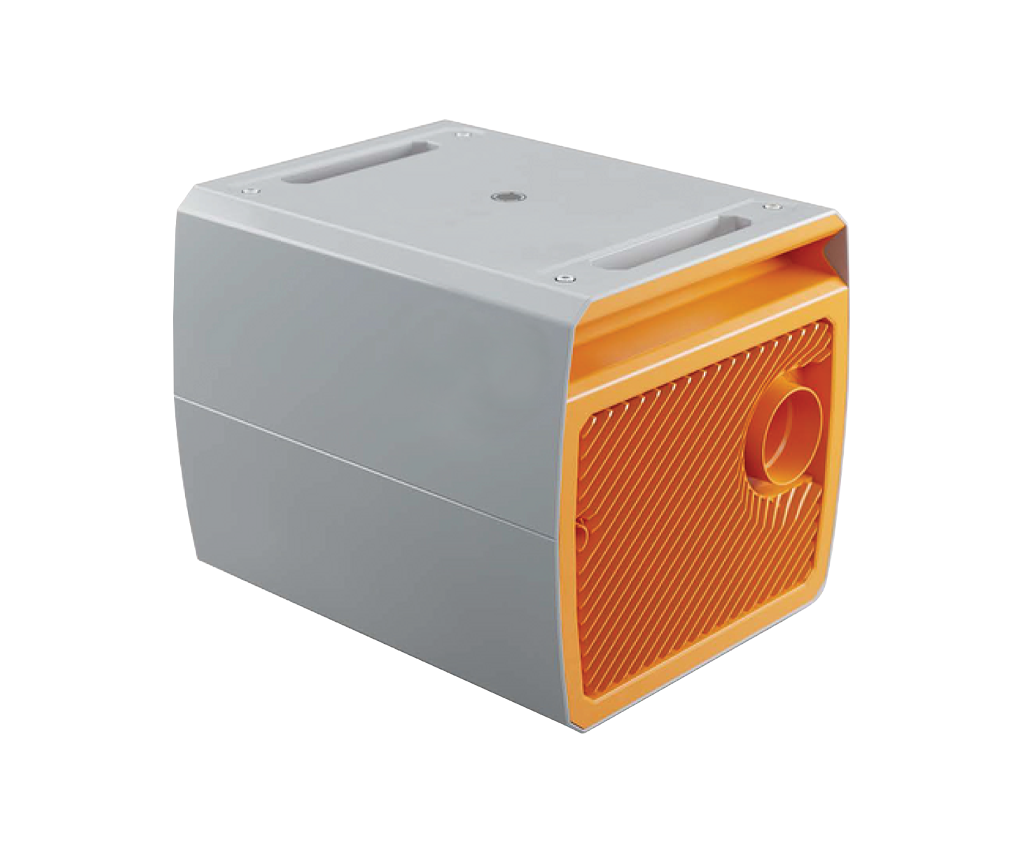

| Dimension L x W x H | 400 mm x 333 mm x 363 mm |

| Weight | 18 kg |

- Hygrostat

The hygrostat switches the dehumidifier to the desired relative humidity [%RV] in the air. - Dew point controller

The dew point controller is equipped with a capacitive humidity sensor and digital readout. The combination of relative humidity [%RV] and dew point temperature [°Cdp], with the possibility of setting e.g. both a set point of 60%RV and a dew point of 10°C, makes the controller suitable for many process applications.

Industries and applications

How our dehumidifiers work

Process air:

- Extracted air is filtered to protect the rotor and prolong its life. The rotor is the most important component of the drying process.

- The rotor, coated with silica gel, adsorbs moisture molecules from the air the process fan passes through it.

- The warmer dry air leaves the adsorption dryer to be fed to the process.

- Process air duct connections are both (in & out) on the left side of the air dryer.

Regeneration air:

- Extracted air is filtered and modulating, energy-efficiently heated.

- Optionally, the air can first be heated by heat recovery. The electric heater then brings the air up to the desired regeneration temperature.

- The regeneration fan feeds airflow through the rotor to expel the water vapour from the rotor and discharge it to the outside.

- The rotor is ready to take up water vapour again.

- Regeneration air channel connections are both (in & out) on the right side of the air dryer.

Mollier diagram

The Mollier diagram, also known as the h-x diagram, is a visual tool used to represent the thermodynamic properties of moist air. The diagram was developed by Richard Mollier in 1923 and is often used in industry for applications such as air handling, refrigeration and heating systems. Our experts at Reinders Industrial can help advise you on the Mollier Diagram.